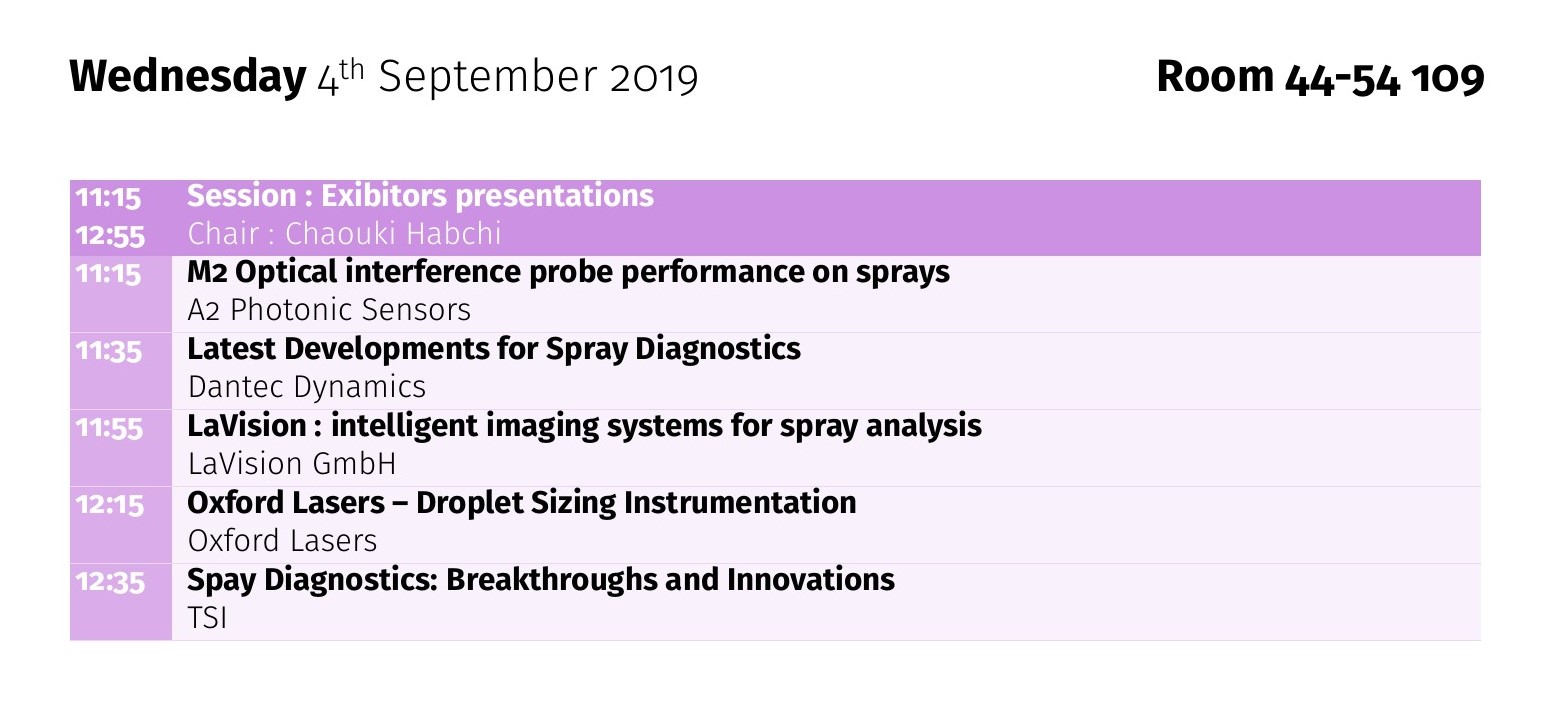

A2 Photonic Sensors

A2 Photonic Sensors designs and manufactures innovative measurement systems for fluid mechanics and earth sciences since 2007. The company’s M2 is a family of advanced measurement devices using a unique technology based on over 20 years of research. It is dedicated to bubbly flow and spray characterization and provides high-accuracy measurements of void/liquid fraction, bubble/droplet velocities and sizes.

The M2 instrument is based on a very thin mono-fiber optical probe, directly immersed in the heart of the flow. The small size of the sensor keeps the disturbance as minimal as possible, and enables the detection of very small bubbles (down to 100 µm depending on operating conditions, such as the velocity of the flow) and droplets as small as 5 µm. Since the sensor is based on a single tip, it provides highly accurate and unambiguous results. A major advantage of the system is its user-friendliness, as it can be installed in minutes and does not require heavy training. Also, as the system does not require any light propagation outside the probe, it can effectively work in very dense flows, which puts it one step ahead from image-based techniques for these environments.

The system has been successfully used in various operating conditions (high pressure, dense flows…) by many academic laboratories as well as in industry, for a wide range of applications: chemical industry, water treatment, hydrology (wave flume, stepped spillways), climatic wind tunnels, turbomachinery nozzles, agricultural sprays and many others.

Please visit www.A2PhotonicSensors.com or our booth at ILASS Paris 2019 for more information

Dantec Dynamics

Scientists and Engineers in fluid dynamics and solid mechanics rely on measurements to make breakthroughs in applied research, technology development, and quality assurance. Dantec Dynamics specializes in the development, manufacture and application support of measurement systems that acquire and analyze data of physical properties in fluids and in solid structures. We deliver turnkey and customized solutions built on high-end laser optics, imaging, and sensor technologies. Our user-friendly software performs advanced data analysis and produces real-time results. Furthermore, we pride ourselves in providing our clients superior technical application support worldwide. You gain accurate measurement results easily and quickly which help you accelerate the pace of discovery, innovation, quality control or NDT. Our distinct competence and experience in integrating measurement methods and technologies into the right solution for you, is unique. Partnering with Dantec Dynamics helps you gain crucial knowledge from any test or measurement campaign. Dantec Dynamics – Turn Measurements into Knowledge

LaVision GmbH

As a supplier of innovative (laser) imaging systems and optical sensors LaVision has established a strong reputation as a solution provider among its customers from various industrial and academic research fields. Very often our systems are used in automotive, aerospace or power generation, e. g. for the development of more efficient and cleaner combustion processes. Multi-dimensional velocity fields in wind tunnels, flame temperature and composition, particle concentrations and diameters are measured in-situ separately or simultaneously with high temporal and spatial resolution. In process engineering our in-situ measurement methods are applied to analyze mixing processes in multiphase flows. Material testing benefits from our highly accurate non-contact measurement systems for deformation and strain measurements.

In process and quality control, e. g. for in-line leakage tests in the pharmaceutical industry or the analysis of spray nozzles for fuel injectors, our systems contribute to a significantly higher product quality.

The LaVision team has extensive professional experience in laser and camera technology, imaging techniques for flow analysis, spectroscopy and digital image processing. LaVision is cooperating with leading research institutions and companies around the globe and is serving the worldwide markets through their subsidiaries or representatives.

Oxford Lasers

As one of the most successful spin offs from Oxford University in 1977, Oxford Lasers have been at the forefront of laser technology for almost 40 years. Through huge shifts in the industrial applications and technological requirements; from uranium enrichment in the 1980’s to high speed imaging for the pharmaceutical market in the 2000’s, Oxford Lasers adapted and brought new laser technology solutions to market. Proving their ability to invent solutions applied not just to laser technology, but to the business too. Oxford Lasers continue to develop new systems and solutions, the substantial R&D department is involved in numerous UK & European research projects which enables them to keep to the forefront of laser micromachining and high speed imaging techniques and technologies. Today, Oxford Lasers operate two divisions of the business, Imaging and Industrial and have locations in America, France and the UK.

Imaging Division

Oxford Lasers Imaging Division offer laser systems, contract services, system rental, R&D and technical support for: High speed imaging, using high speed cameras, lasers and software to offer complete imaging solutions. Oxford Lasers have significant experience within the field of spray characterisation, providing information on droplet size, droplet velocity and droplet shape. The VisiSize instrument range provides a range of capability to suit the different measurement challenges present in the field.

Industrial Division

Oxford Lasers Industrial Division offer the full spectrum of fully automated Laser Micro-Machining Tools from Compact Laser Micromachining Tools; perfect for R&D and Pilot Production, through to Ultrafast Laser Micromachining Tools; utilising the highest precision industrial laser technology. In conjunction with providing a significant range of Laser Micromachining Tools, Oxford Lasers Industrial Division also offer Subcontract Laser Micromachining Services. With nine in-house Laser Micromachining systems, capabilities include micro-drilling, milling, patterning, scribing and cutting in a vast array of materials from Metals to Glass and have covered over 10,000 niche applications across a variety of sectors.

TSI

TSI offers a complete line of products for spray diagnostics. Products include Phase Doppler Particle Analysis (PDPA) systems, Time-Resolved Particle Image Velocimetry (TR-PIV) systems, Global Patternation Systems, Global Sizing Velocimetry (GSV) systems, and Quantitative Flow Visualization systems. These systems are used to characterize various aspects of a spray; from measuring droplet velocity and size at a specific location, to obtaining global information of the ligament formation, to identifying the breakup in a spray. Many of these systems are complementary to one other, helping the user to obtain the complete diagnostics of a spray.

The next generation of the PDPA system: the Powersight is compact, simple to use, and flexible with more laser power. For real-time instant velocity or simultaneous velocity and size measurements, the Powersight provides a higher laser power up to 500 mW per channel, increasing the capability of making measurements in challenging environments, like for GDI dense spray and large facilities with long focal standoff of several meters. The new FSA3800 processor combines signal analysis and photo-detection together for simple operation. The Powersight and FSA processor give you the powerful system arrangement of LDV and PDPA measurements.

TSI’s Fluid Mechanic Systems can be easily configured to meet your current application and also be expanded for future applications. Contact TSI by phone at +33 (0)1 41 19 21 99, online at www.tsi.com, or stop by TSI’s booth to learn more about our systems and how our measurement systems can meet your challenging research today.